EMI Gaskets

Modern engineers recognize the prevalence and importance of protecting electronics from EME (electromagnetic energy). Without basic awareness of EMI and its potential harm to electronics, designs often lack the appropriate protection against radio frequency spectrum and electromagnetic fields. Without protecting against EMI and RFI, it is common for devices to malfunction.

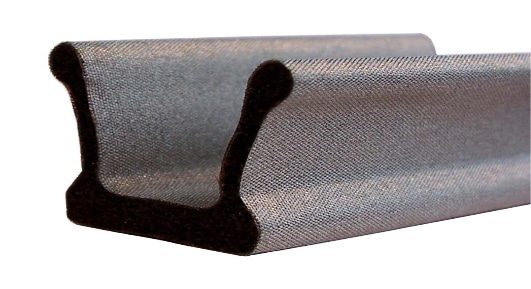

There are many tools engineers use, from EMI shielding to conductive foam. One of the most used devices is an EMI shielding gasket. These types of gaskets are mechanical devices that are designed to protect electronics from EMI. EMI shielding gaskets are relatively new because traditionally, EMI shielding was fabricated from sheet metal formed into shapes creating enclosures and electronic housing. Copper, steel, and aluminum R robust and rigid materials, but when pressed thin into sheets, they can easily deform under pressures necessary for adequate sealing. After EMI Shields deform, they begin to leak EMI to and from the circuit.

Modern EMI shielding material includes a combination of metal wires, metal screens, and metal foams. For extra performance enhancement, coatings of metallic inks or plied to the inside of the enclosure. EMI gaskets are used in rugged touchscreens constructed of particle-filled silicone. These gaskets can attenuate EMI emissions while also creating strong electrical conductivity. EMI gaskets allow engineers to ensure the most robust levels of environmental sealing in extreme conditions (Arctic cold and desert heat). EMI shields and gaskets cushion the device from potential mechanical shocks. To do this, they must be soft enough to avoid interfering with any display touch functions.